Laser Knowledge | Technotes

Welcome to our category page “Laser knowledge | Technotes ”!

Here we offer you valuable insights into the world of diode laser technology to give you a better understanding of our products. Whether it’s general information on diode lasers, detailed facts about blue diode lasers, or technical explanations of laser drivers and laser chillers – we provide you with the knowledge you need to make informed decisions.

The laser world is complex and diverse, and we want to help you better understand the most important basics as well as advanced concepts. By familiarizing yourself with the technical details, you can classify our products in a targeted manner and find out which solutions best suit your individual requirements. We are convinced that well-informed customers achieve the best results – whether in research, industry or private use.

Our knowledge platform is aimed at both beginners and experienced users. Take the opportunity to obtain comprehensive information and fully exploit the potential of our diode lasers, drivers and cooling systems.

Immerse yourself in the fascinating world of lasers and be inspired!

Introduction

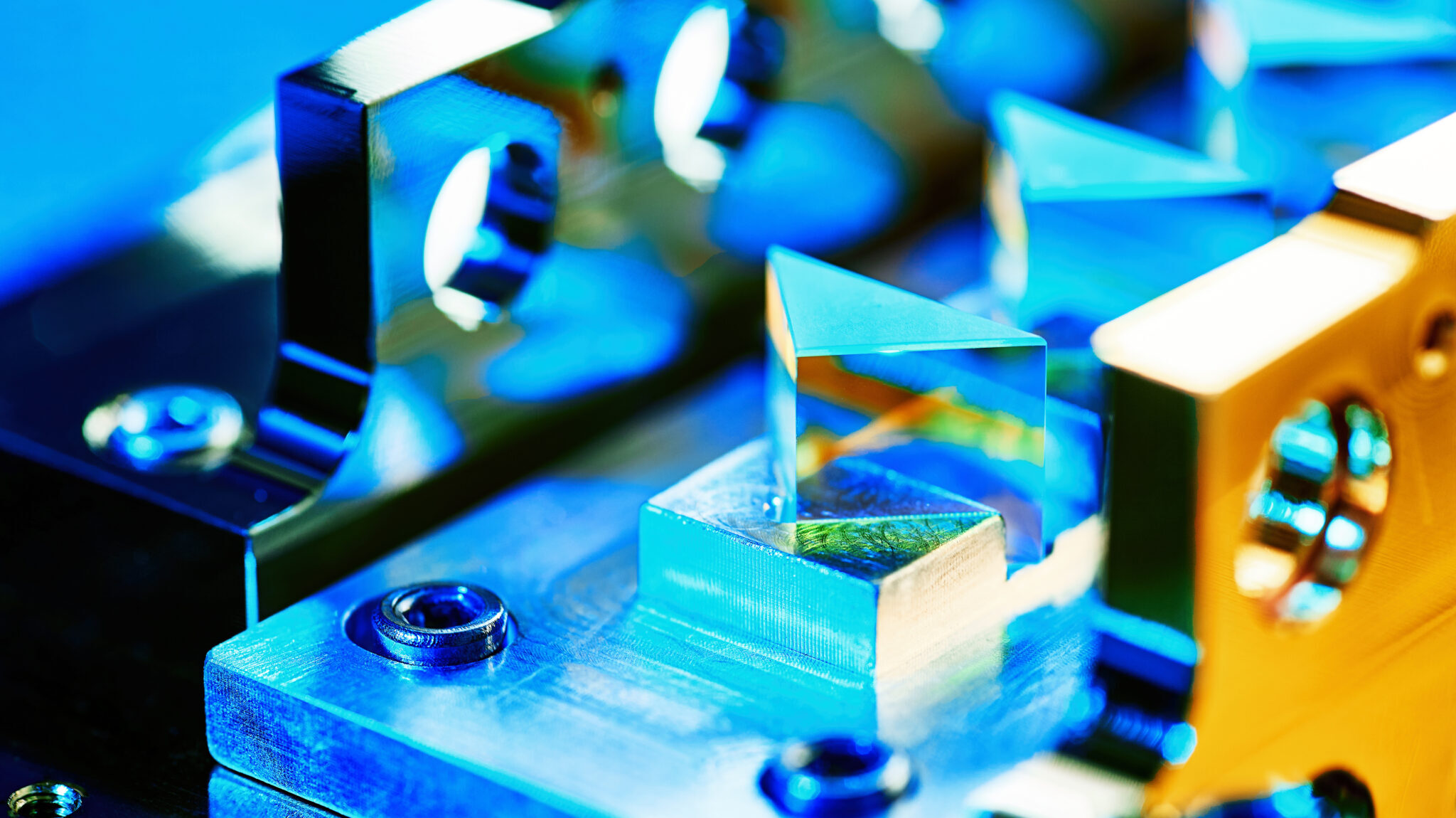

In recent decades, diode laser technology has become an essential component of modern laser applications in science, industry and medicine. Diode lasers, also known as semiconductor lasers, are based on the use of semiconductor materials to generate coherent light, which distinguishes them from other types of lasers such as gas lasers or solid-state lasers.

Functional principle of diode lasers

Diode lasers consist of a p-n junction layer, which is created by doping various semiconductor materials. By applying a voltage across this layer, electrons and holes are injected into the active area, where they recombine. During this recombination process, photons or light particles are released. These emitted photons are amplified by optical resonators, resulting in laser radiation. The special thing about diode lasers is that they are directly electrically pumped, which makes them compact, efficient and versatile.

Properties and advantages of diode lasers

High efficiency: Diode lasers have a high electrical efficiency, often over 50 %, which makes them the most energy-efficient laser types. This means that they require less energy to achieve the same optical power compared to other laser sources.

Compact design: Due to their simple structure, diode lasers are usually extremely compact and lightweight, making them ideal for portable devices and applications where space and weight are important.

Wide range of applications: Diode lasers can emit light in a wide range of wavelengths, from the near UV to the far infrared. This enables adaptation to specific applications, whether in medical technology, industrial production or telecommunications.

Robustness and durability: Diode lasers are robust and have a long service life, which makes them particularly attractive for industrial applications where reliability is crucial.

Fields of application for diode lasers

Telecommunications: Diode lasers are the driving force behind fiber optic technology. They are used to transmit light signals over long distances with minimal loss, which forms the basis of the modern internet. With the ability to transmit data at extremely high speeds, they enable communication over long distances.

Medical applications: In medicine, diode lasers are used for a variety of therapies, including surgical procedures, treatment of skin conditions and eye surgery (e.g. LASIK). They provide precise incisions with minimal tissue damage and reduced healing time.

Material processing: Diode lasers are widely used in industrial production, e.g. for welding, cutting and engraving metals or other materials. In addition to classic processes, diode lasers are also ideal for micro material processing, such as stripping fine wires or making electrical connections by soldering or welding. They offer high precision and are ideal for applications where precise control of power and focus is required.

Sensors and measurement technology: In sensor technology, diode lasers are used for high-precision measurements, e.g. in rangefinders, speed detectors or spectroscopy applications. Their ability to emit light in narrow wavelength ranges enables the precise analysis of materials and environments.

Future developments and potential

The development of diode laser technology is progressing continuously. Current areas of research are focusing on optimizing beam quality, increasing output power and improving service life. Another important topic is miniaturization, as more and more applications could benefit from smaller, more efficient and more powerful lasers.

Conclusion

Diode lasers have shaped and revolutionized modern technology in many areas. Their efficiency, compactness and versatility make them an indispensable technology in numerous industries. With continued research and development, future generations of diode lasers could become even more powerful and cost-efficient, enabling new applications and innovations in a variety of fields.

Introduction

Blue laser technology has made significant progress in recent years and is currently revolutionizing various industries. Blue lasers, which emit light with a wavelength of between 400 and 500 nanometers, play a key role in a wide range of applications – from manufacturing to medicine.

Functionality and technical principles

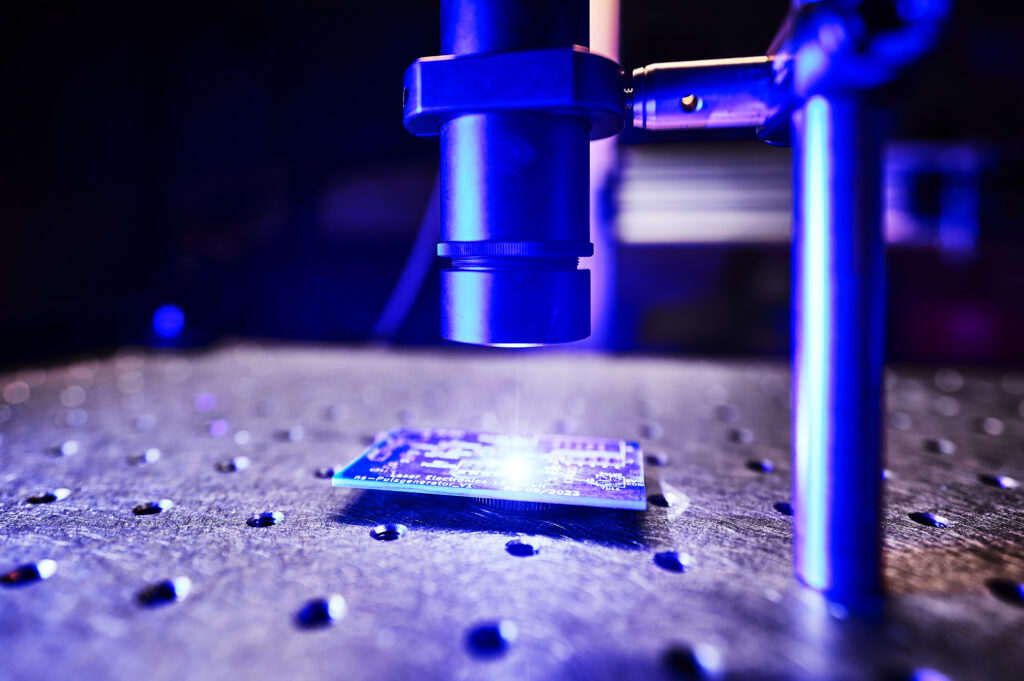

Blue lasers use gallium nitride (GaN) semiconductor materials, which are particularly suitable for generating light in the blue and ultraviolet range. These lasers offer several key advantages over red and infrared lasers when exciting many materials, including higher process efficiency and greater radiation density. This allows them to cut, weld and engrave more precisely and quickly, making them valuable in industrial applications such as microelectronics manufacturing.

Areas of application

- Industrial manufacturing: Blue diode lasers are used in micro-manufacturing, as their shorter wavelength allows for more precise cuts than red or infrared lasers They are used in precision mechanics and display production, for example, to make thinner and more precise cuts.

- Medical applications: In surgery and dermatology, blue light technology offers advantages as it has a high absorption rate in tissue. This results in high process efficiency, precise cuts and minimal thermal damage, which is particularly beneficial in eye and skin surgery.

- Optical storage media: In Blu-ray discs, one of the most well-known areas of application, blue lasers enable higher data density. Compared to red lasers, which are used in CDs and DVDs, blue lasers can read and write data in a much smaller space.

- Lithography and 3D printing: Blue diode lasers are also used in semiconductor lithography, where extremely fine structures are required. The technology is also used in the field of 3D printing, where precise exposure is crucial.

Advantages and future prospects

Blue lasers not only offer more precise processing, but also a longer service life and better energy efficiency for various materials compared to other types of laser. These advantages make them an attractive option for industry. The development of ever more powerful blue diode lasers with higher outputs and new wavelengths is expected to open up even more fields of application.

In the future, blue lasers could also play a role in communications technology and even in space travel, as they are suitable for high-precision measurements and data transmission.

Conclusion

Blue laser technology is an innovative and growing field that is transforming various industries. Its advantages in precision, energy efficiency and performance make it a key technology for manufacturing, medicine and electronics of the future.

Introduction

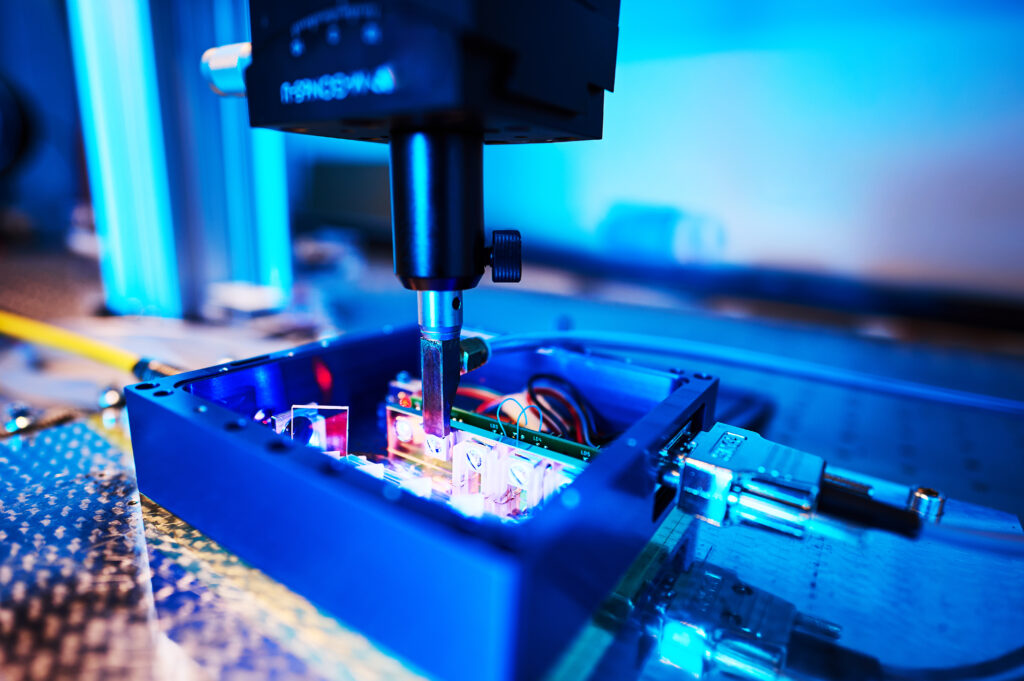

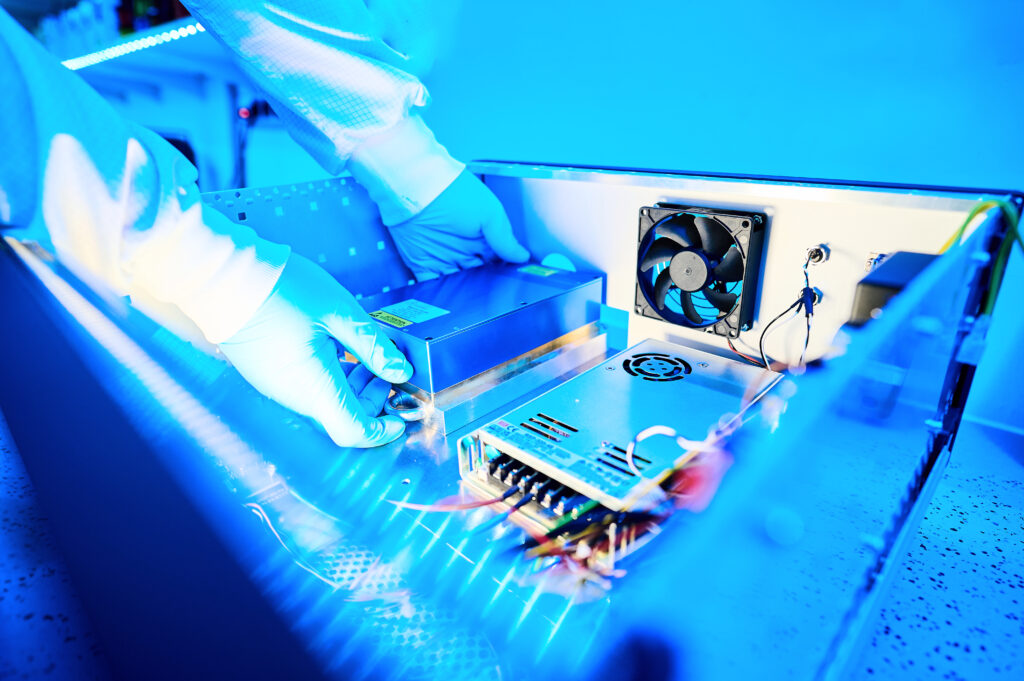

Laser driver technology plays a crucial role in the operation and efficiency of laser systems. A laser driver is an electronic device that is responsible for precisely controlling and supplying laser diodes with the required electrical energy. Without this technology, the use of diode lasers in such a wide range of applications, from industrial production to medical technology, would be inconceivable.

Functionality and technical aspects

Laser drivers ensure that the current flowing through a laser diode is precisely controlled. This precision is crucial, as even small fluctuations in the current can lead to instabilities in the laser output or even to the destruction of the sensitive laser diodes. The main tasks of a laser driver include:

- Current control: A laser driver ensures that the laser is operated with exactly the right current to achieve the desired optical output.

- Temperature management: As laser diodes are very sensitive to temperature, our drivers have systems to monitor and regulate the temperature. This prevents overheating, which could lead to loss of performance or damage.

- Pulsed operation: Some applications require the emission of laser pulses instead of a continuous beam. Our laser drivers designed for this purpose are able to precisely control this pulsed power supply, which is important for high-speed communication or medical laser applications.

- Laser safety: Laser drivers also have the task of ensuring the necessary laser safety so that no dangerous power emissions can occur. For this purpose, electronic safety devices specially designed for diode laser operation are built into our drivers.

Different types of laser drivers

- CW (continuous wave) laser drivers: These drivers are designed for continuous wave or continuous operation of semiconductor lasers and provide a constant power supply for applications such as laser material processing or laser engraving where a continuous beam is required.

- Pulsed laser drivers: For applications that require fast and precise laser pulses – such as LIDAR technology or ultra-fast optical communication systems – pulsed laser drivers are used. They must be extremely precise in order to generate high-frequency pulses without delay or noise.

- Modulation laser drivers: These drivers make it possible to dynamically modulate or adapt the power of a laser, which is crucial for applications such as optical data transmission or special medical applications.

Possible applications

- Industrial manufacturing: Laser drivers play a central role in precision manufacturing, for example in cutting, welding and engraving with lasers. The exact control of the laser power makes it possible to process materials precisely.

- Medicine and research: In medical technology, laser drivers ensure the precise use of laser beams in surgical applications or dermatology. They enable high-precision control of laser beams to cut or treat tissue without damaging neighboring areas.

- Telecommunications: In optical data transmission, for example in fiber optic networks, extremely fast laser pulses are required to transmit huge amounts of data in fractions of a second. Laser drivers ensure that these pulses are generated with the necessary frequency and accuracy.

Challenge: precision and safety

One of the biggest challenges in the development of laser drivers is the balance between performance and safety. Overheating or overvoltage can destroy laser diodes very quickly. Efficient thermal management is therefore crucial. Our high-quality laser drivers have temperature monitoring systems that automatically stop or adjust the operation of the laser in the event of overheating.

In addition, the trend towards ever more powerful lasers requires advanced laser drivers that are capable of delivering higher currents and voltages without damaging the sensitive laser diodes.

The future of laser driver technology

With the rapid progress in laser technology, the need for more intelligent and efficient laser drivers is also growing. Drivers will play an even more central role, particularly in research and development, such as in quantum communication, where the precision of lasers at the atomic level is required. The transition to automated manufacturing processes and autonomous vehicles with LIDAR systems will also continue to drive the development of laser drivers.

Conclusion

Laser driver technology is the invisible hero behind advances in laser applications. It enables precise control, protects sensitive laser diodes, optimizes the efficiency of laser systems and protects the user from dangerous laser radiation. Its importance will continue to grow in the future as more and more technologies – from industry to medicine – rely on the advanced control of lasers.

Introduction

Laser cooling system technology is an essential component of modern laser systems. It ensures that laser diodes and other components are cooled or temperature-stabilized during operation to prevent overheating and the associated damage or loss of power. As laser diodes are particularly sensitive to temperature changes, an effective cooling system is crucial for the stability, efficiency and service life of the laser.

Why is cooling so important for lasers?

Laser beams are generated by the electrical drive of laser diodes or laser media, which generate a lot of heat in the process. If this heat is not dissipated, it can lead to a drop in performance:

- A drop in performance, as higher temperatures reduce the efficiency of light emission,

- Deterioration of the beam quality, which has a negative effect on the precision and sharpness of the laser,

- Structural damage to the sensitive laser diodes, which may require expensive repairs or replacement.

High-power lasers in particular, which are used over long distances in industrial production, medicine or telecommunications, generate large amounts of heat that could not be managed without advanced cooling systems.

Types of laser cooling systems

Active and passive cooling systems: Passive cooling systems rely on natural heat radiation (e.g. via heat sinks), while active systems such as fans or pumps dissipate the heat in a targeted manner. In high-performance applications, active cooling systems are essential to ensure constant operating temperatures.

Air-cooled systems: These cooling systems use fans and cooling fins to dissipate the heat generated by the laser diode into the ambient air. They are widely used in smaller and less powerful laser systems as they are a simple and cost-effective solution. However, air-coupled cooling systems are less efficient when it comes to high-power lasers, as the air only offers a limited heat capacity for dissipation.

Water cooling: Water cooling is the preferred cooling method for more powerful laser systems. Here, a liquid circuit is used in which water (or another cooling liquid) is pumped through the laser system to absorb and dissipate the heat. Water has a high heat capacity, which means it can efficiently transport large amounts of heat. The amount of heat absorbed in the area of the laser is usually transferred to an air-coupled cooling system, where the heat energy absorbed by the cooling medium is released into the environment (and thus out of the cooling system). This method is very popular with industrial lasers that are operated at high power for long periods of time.

Thermoelectric cooling systems (Peltier elements): These systems work on the basis of the Peltier effect, in which an electrical current is used to generate a temperature difference in the material. They are particularly suitable for compact laser systems where space is at a premium. This type of cooling allows precise temperature control and is ideal for applications in which smaller laser modules, laser diodes or laser chips are used, for example in micro material processing, medical technology or telecommunications.

Application of laser cooling systems

- Industrial lasers: In manufacturing technology, where lasers are used for cutting, welding and engraving, temperature stability is crucial for process precision and speed. Without effective cooling systems, such lasers could not be operated continuously at peak performance.

- Medical lasers: In medicine, especially in eye and skin surgery, lasers often operate at very high energy densities. Precise temperature control through cooling is necessary in order to focus the laser beam accurately and avoid thermal damage to surrounding tissue.

- Telecommunications: In optical communication, for example in fiber optic networks, laser diodes are responsible for transmitting data as light pulses. These laser diodes must be operated constantly at low temperatures in order to ensure consistently high data transmission.

Innovations in laser cooling system technology

Modern developments are aimed at more compact and energy-efficient cooling systems. Especially in areas such as quantum communication or space technology, where precise laser technologies are used under extreme conditions, the development of new cooling solutions is crucial. Advanced materials such as liquid metals or special nanomaterials are used here, which could improve heat dissipation even further.

The integration of intelligent monitoring systems that automatically regulate the temperature is also becoming increasingly important. These systems monitor the temperature of the laser diodes in real time and dynamically adjust the cooling capacity to ensure maximum efficiency.

Challenges and future prospects

One of the biggest challenges is to develop powerful yet compact cooling systems that are also suitable for smaller laser systems. In the miniaturization of laser systems – especially for portable devices such as those used in analytics, medicine or communication – cooling solutions must be integrated without compromising size or energy efficiency.

In the future, new approaches such as the use of nanofluids (liquids with nanoparticles dispersed in them that improve thermal conductivity) or the further development of cryogenics for extreme cold could further increase the efficiency and performance of cooling systems.

Conclusion

Laser cooling system technology is essential for the safe and efficient operation of lasers. Whether in industrial production, medicine or telecommunications, well-designed cooling systems make it possible to exploit the full potential of lasers without damaging the sensitive components. With the constant advances in cooling technology, it will be possible to develop even more powerful, compact and efficient laser systems in the future.